7 Expert Tips for Installing Lightweight Anchoring Systems Safely

How Anchoring Equipment Enhance Security and Security in Numerous Industries

Anchoring systems are necessary for making certain safety and stability across several industries. They supply important support for frameworks, devices, and employees, mitigating threats associated with vibrant problems and side forces. From construction websites to maritime settings, these systems offer diverse functions. Their effectiveness is frequently considered granted, yet the nuances of their application can greatly affect operational success. Understanding their value discloses deeper insights right into market security criteria and methods.

The Importance of Anchoring Systems in Safety Protocols

Frequently forgotten, securing systems play a crucial role in guaranteeing security throughout numerous markets. These systems supply security and assistance for frameworks, devices, and personnel, consequently minimizing the danger of accidents and injuries. In settings such as construction sites, maritime procedures, and commercial centers, efficient anchoring guarantees that heavy machinery and scaffolding continue to be protected, preventing devastating failures. Furthermore, appropriate anchoring systems can improve the efficiency of individual protective equipment, such as harnesses, by anchoring them to secure factors, which is important for workers running at heights. Making use of reputable anchoring protocols cultivates a security culture, where both monitoring and workers prioritize risk mitigation. Eventually, the assimilation of well-designed anchoring systems into safety procedures is critical for maintaining functional stability and protecting human life, highlighting their relevance in day-to-day safety actions throughout varied fields.

Kinds Of Anchoring Equipments Used in Building

Additionally, ground supports are important for stabilizing structures in difficult surface, supplying resistance versus lateral pressures. Tiebacks and dirt supports are utilized in excavations and maintaining wall surfaces to enhance security against dirt pressure. Each sort of securing system is created to meet particular lots demands and ecological problems, adding to the overall security and sturdiness of construction projects.

Anchoring Solutions for Maritime Stability

Effective securing solutions are important for ensuring maritime security, specifically in dynamic aquatic atmospheres. These solutions play an important function in securing vessels, offshore platforms, and drifting frameworks versus unpredictable pressures such as waves, currents, and wind. Various kinds of supports, including typical stockless supports, drag supports, and suction supports, are used based on details operational demands and seabed conditions.

The layout and selection of securing systems are affected by variables such as water deepness, soil structure, and ecological problems. Advanced technologies, consisting of dynamic placing systems and real-time monitoring, better improve the effectiveness of securing services. By giving a stable foundation, these systems considerably reduce the danger of capsizing or wandering, consequently making certain the safety and security of employees and cargo. Ultimately, durable anchoring remedies add to the operational effectiveness and longevity of maritime properties, highlighting their value in the maritime sector.

Aerospace Applications: Maintaining Airplane Secure

In the aerospace industry, making certain the protection of airplane entails numerous tie-down strategies and cargo safeguarding approaches. Conformity with safety laws is important to keeping security during ground procedures and transport. These practices are essential for avoiding mishaps and ensuring the security of both the airplane and its owners.

Aircraft Tie-Down Techniques

While the safety and security of aircraft is extremely important, appropriate tie-down strategies function as a crucial aspect in assuring security during ground operations. Aircraft tie-downs entail protecting the aircraft to the ground using ropes, chains, or specialized bands, stopping undesirable motion as a result of wind or other environmental factors. Reliable strategies include making use of appropriate anchor factors and using a sufficient variety of tie-downs based upon the aircraft's size and weight. Normal examinations of tie-down tools are important to assure integrity and effectiveness. In addition, recognizing regional climate condition can assist the selection of approaches and materials used for safeguarding aircraft. Ultimately, carrying out sound tie-down techniques improves functional safety and protects against damage throughout periods of inactivity.

Cargo Protecting Methods

Freight protecting methods play a crucial role in preserving the stability and safety of aircraft during transportation. Reliable systems ensure that freight continues to be steady and protected throughout the trip, lessening the risk of movement that could lead to harm or mishaps. Usual methods include the use of freight webs, straps, and specialized locking gadgets designed to stand up to the pressures experienced during landing, flight, and launch. The implementation of these methods includes careful planning and consideration of the freight's weight circulation and center of gravity. In addition, tools such as tons binders and edge protectors improve the overall effectiveness of protecting techniques. By employing these approaches, the aerospace market substantially lowers potential risks linked with transferring products, eventually guarding both the aircraft and its freight.

Safety And Security Rules Conformity

Ensuring compliance with security policies is essential for keeping the protection of airplane and their freight. In the aerospace market, stringent adherence to policies set by regulating bodies, such as the Federal Air Travel Administration (FAA) and the International Civil Aeronautics Organization (ICAO), is vital. These guidelines mandate the use of trusted anchoring systems to safeguard freight and stop moving throughout trip, which can result in accidents. Proper training for personnel in the use of these systems is also necessary to confirm their performance. Regular examinations and upkeep of anchoring tools better boost compliance and safety. By sticking to these regulations, the aerospace sector can greatly lower dangers, protect lives, and keep operational website link honesty in flight.

Manufacturing Security: Role of Anchoring in Manufacturing

In the domain of production, anchoring systems play a necessary duty in guaranteeing tools stability and protecting against office accidents. By firmly attaching equipment, these systems not just improve safety and security however additionally add to functional effectiveness. Effective securing methods can greatly minimize the threat of events, advertising a much safer workplace.

Equipment Security Assurance

The production setting frequently includes hefty machinery and facility tools, the effectiveness of anchoring systems plays a significant duty in maintaining equipment stability. Correctly mounted supports lower resonances and prevent equipment from shifting during operations. This stability is vital for both the performance of equipment and the total performance of manufacturing processes. In addition, well-anchored tools lessens deterioration, expanding the life expectancy of costly assets. In atmospheres where precision is paramount, such as production line, the guarantee of security offered by anchoring systems enhances operational precision. Subsequently, incorporating robust anchoring services into manufacturing arrangements not just safeguards tools but likewise cultivates a dependable production landscape, eventually adding to improved result and efficiency.

Avoiding Work Environment Accidents

Securing systems substantially add to preventing work environment accidents in manufacturing atmospheres. By safeguarding machinery and equipment, these systems decrease the threat of tipping, dropping, or moving during procedure. This stability is important, as unanchored equipment can bring about major injuries among workers and damages to residential property. Furthermore, anchoring systems boost the performance of safety and security protocols, as they supply a trustworthy structure for security actions such as guardrails and safety and security internet. Normal evaluations and upkeep of securing systems are necessary to assure their honesty, therefore cultivating a society of safety within the office. Ultimately, a durable anchoring system is a basic part in creating a safer production atmosphere, reducing the likelihood of crashes and promoting total work environment safety and security.

Improved Functional Efficiency

Enhancing operational efficiency in producing relies substantially on reliable anchoring systems. These systems supply security to equipment and equipment, reducing resonances and activity throughout production processes. By making certain that tools and elements remain firmly in location, securing systems lower the threat of operational delays caused by tools imbalance or failing. This integrity enables smoother process and increased performance, as employees can concentrate on their tasks without constant modifications or disturbances. Additionally, reliable securing contributes to the durability of equipment, lowering upkeep costs and downtime. Consequently, suppliers can attain higher outcome prices and improved source usage, inevitably resulting in greater success and a competitive side in the market.

Developments in Anchoring Modern Technology

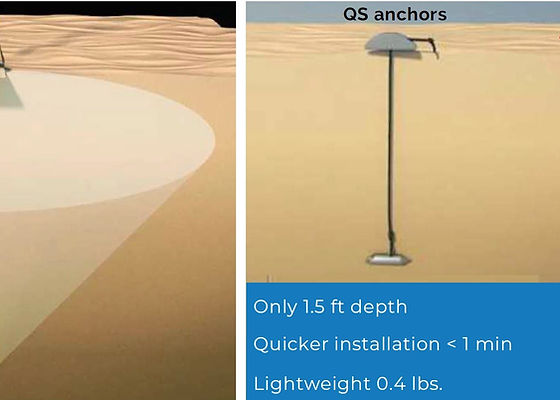

As the needs for security click reference and security in various markets raise, innovations in anchoring modern technology have arised to deal with these obstacles. Modern anchoring systems are now developed with advanced materials and design techniques, improving their longevity and efficiency. Innovations such as clever sensing units and automated surveillance systems permit for real-time analysis of anchoring efficiency, making certain suitable safety steps are maintained.

Furthermore, lightweight composite materials have actually changed conventional steels, decreasing the general weight of securing systems while improving strength. Modular layouts supply versatility, enabling for easy changes and personalizations to meet particular operational requirements. Green anchoring remedies are getting traction, reducing environmental impact while making sure durable performance.

These advancements not only boost the dependability of securing systems however also deal with the progressing needs of varied markets, consisting of construction, marine, and renewable energy fields. Such advancements lead the way for safer and more effective operations across various applications.

Situation Studies: Successful Implementation of Anchoring Systems

The developments in anchoring innovation have actually brought about significant study showcasing effective executions throughout various industries. In the construction sector, a major project made use of a new kind of deep structure anchoring system, which boosted stability in difficult soil conditions. This technology considerably reduced negotiation concerns and assured safety and security throughout building, ultimately resulting in prompt project completion.

Likewise, in the maritime industry, a delivery firm took on innovative mooring systems that enhanced vessel security throughout damaging weather. This implementation caused a significant reduction in accidents and cargo losses, underscoring the value of trusted anchoring in uncertain settings.

Furthermore, in the wind energy market, securing systems have actually been vital in protecting overseas generators versus solid currents, showing their duty in lasting power manufacturing (Portable Building Anchors). These study collectively illustrate just how effective anchoring services add to safety, effectiveness, and long-lasting practicality across varied markets

Regularly Asked Inquiries

Exactly How Do Anchoring Systems Affect Overall Task Timelines?

The effectiveness of project timelines can be greatly affected by anchoring systems. Correct anchoring lowers delays by ensuring security, reducing threats, and assisting in smoother operations, inevitably adding to prompt task conclusion and improved productivity.

Are There Specific Laws Governing Anchoring Systems?

Specific regulations governing securing systems exist throughout numerous markets, making sure conformity with security requirements. Lightweight Anchoring Systems. These regulations commonly focus on maintenance, setup, and layout, aimed at lessening threats and enhancing Click This Link general functional stability and security

What Products Are Frequently Made Use Of in Anchoring Systems?

Typical materials utilized in anchoring systems include high-strength steel, galvanized iron, synthetic ropes, and composite materials. These elements are selected for their resilience, resistance to ecological factors, and capacity to give reliable assistance in various applications.

Just How Commonly Should Anchoring Solutions Be Evaluated?

Inspection regularity for anchoring systems typically depends upon usage and environmental conditions. Usually, it is advised to carry out examinations every six months, with more regular sign in rough atmospheres or adhering to significant events affecting security.

What Are the Costs Connected With Setting Up Anchoring Systems?

The expenses related to installing securing systems vary considerably based upon factors such as materials, layout intricacy, and labor needs. Correct budgeting is vital to assure effective implementation and compliance with security laws in relevant markets.

Securing systems are crucial for making certain security and security throughout multiple sectors. Frequently ignored, anchoring systems play an essential role in ensuring security across different markets. In enhancement, securing systems boost the effectiveness of security methods, as they provide a trustworthy structure for safety measures such as guardrails and safety and security internet. Routine examinations and maintenance of anchoring systems are necessary to assure their honesty, consequently cultivating a society of safety and security within the office. Details laws controling anchoring systems exist across different industries, making sure conformity with safety and security standards.